Sewing Machine Walking Foot: The Definitive Guide

The Definitive Guide: Sewing Machine Walking Feet

Why use a walking foot at all?

Why use a walking foot on your sewing machine? Great question.

As a sewing machine sews, it feeds the fabric forward a designated length of space between each stitch— stitch-feed-stitch-feed-stitch-feed.

The presser foot holds the fabric down against the gripped feed teeth (also known as feed dogs) which are positioned below the needle plate. As the needle goes up out of the fabric, the feed dogs rise just above the needle plate surface and move to feed the fabric forward. When the needle goes back down into the fabric to make the next stitch, the feed dogs disappear momentarily below the needle plate.

And so it goes… stitch-feed-stitch-feed-stitch-feed.

When we use a sewing machine, we are typically sewing multiple layers of fabric together. The feed dogs only make contact with the bottom layer of fabric, not the top layer.

Because the bottom layer of fabric is in contact with the gripped feed teeth and the top layer is not, a potential problem arises: the bottom layer of fabric may feed at a slightly different rate than the top layer. I've heard many people, particularly quilters, refer to this problem as slippage.

In essence, a walking foot is a presser foot with gripped feed teeth— gripped teeth that make contact with the top layer of fabric.

The basic idea is that you can combat slippage and achieve a more even feed between multiple fabric layers by using a walking foot because you essentially have feed dogs that are feeding both the top layer of fabric and bottom of layer of fabric— also known as dual feed.

There are a few things I want to point out.

First, notice how the walking foot has a lever that goes around the needle bar set screw. The walking foot is designed like this because the movement of needle bar moving up and down that causes the action of the walking foot’s gripped feed teeth. In other words, the walking foot reacts to the needle movement, which is fine, but not ideal.

The second thing I want you to notice is the gripped feed teeth on the walking foot itself.

The teeth are made of plastic.

Again, this is fine, but not ideal.

Below are a few of our favorite machines that take an entry-level walking foot.

Janome AcuFeed Flex Walking Foot

Janome calls this walking foot the AcuFeed Flex System and I would argue that it is the best-performing walking foot in the world.

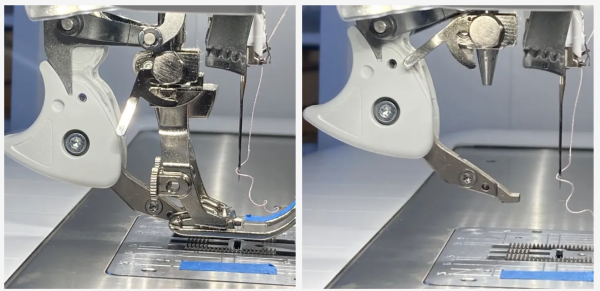

As you can see in the photo above, there is no lever that goes around the needle bar screw, meaning that, unlike the entry-level walking foot, the action of the walking foot's gripped feed teeth is not dependent on the movement of the needle bar.

That begs the question-- how does the walking foot's gripped teeth move?

As you can see in the photo above, the Janome AcuFeed walking foot hooks into a mechanism in the back of the machine. Remember the old song about the thigh bone connects to the knee bone, the knee bone connects to the shin bone, and so on? The same principle applies here. The walking foot is hooked into a mechanism that connects it to the upper shaft of the machine. The upper shaft is connected to the motor belt and the motor belt is connected to the lower shaft. And guess what the lower shaft is connected to? The machine’s feed dog mechanism.

I point this out because this unison of movement gives Janome’s Acufeed walking foot the distinction of integrated dual feed. Because the AcuFeed foot is directly hooked into the machine’s critical internal components, the gripped feed teeth operate completely in sync with the machine's feed dogs, which helps deliver a more perfect even feed than a basic entry-level walking foot.

Not only does it help prevent slippage, not only does it deliver a more even feed when sewing multiple layers of fabric, it does a third thing that is really unique.

A machine that is compatible with Janome's AcuFeed walking foot will have a knob on the right side of the machine that allows you to adjust the feeding ratio between the Acufeed walking foot and the feed dogs. This ability to adjust the feeding ratio is what we call differential feed. Most of you will be familiar with sergers, which are particularly suited for sewing knits. One reason they are well-suitrd for knits is because they are designed with two sets of feed dogs below the needle plate and the ability to adjust the feed ratio between the two feed dogs.

Until Janome invented the AcuFeed walking foot, sewing machines were not capable of differential feed. Now they are. It’s a true evolution in the capabilities of sewing machines, and I expect other manufacturers to follow their lead.

Janome sewing machines with this AcuFeed Flex Walking Foot System:

Bernina Built-in Dual Feed

Bernina has an integrated walking foot of their own, which is commonly known as "built-in dual feed."

As the name implies, this version of a walking foot is built into the machine. The benefit of this design is that it is super easy to engage the walking foot. All you have to do is pull the dual feed down into the presser foot and you’re ready to go.

Those of you who have used the traditional style walking feet before will know it can be a bit of a pain to remove the entire presser foot and ankle, then have to screw on the walking foot while also getting that lever around the needle screw bar. With Bernina's built-in dual feed, you won't have to pull out a screwdriver to put it on and take it off. There is no struggling to get the walking foot lever over the needle screw. You simply pull down the dual feed to engage it, and you push it back up to disengage it.

Similar to Janome's AcuFeed system, Bernina's built-in walking foot also meets the criteria to be classified as integrated dual feed. It does not have as many gripped feed teeth as the Janome walking foot, but the teeth are also made of metal and overall it performs extremely well.

Another unique thing about Bernina's built-in dual feed is that it is compatible with a ton of different feet. If you see a Bernina presser foot with the letter 'D' after the number, that means it is compatible with the built-in dual feed.

The one downside of Bernina’s built-in dual feed is that the machines that have it are rather expensive. As far as I’m aware, at the time I write this newsletter the least expensive Bernina machine that offers built-in dual feed is the B570, which sells for around $4,000.

If someone wants a quality machine with built-in dual feed, but does not want to spend thousands of dollars, they should consider a pre-owned Bernina or a vintage Pfaff machine from 80’s/90’s/early 2000’s— e.g. 7550, 2140, 2022, etc.

Bernina Machines with built-in dual feed: