Sewing Machine Motors

The 2 Types of Sewing Machine Motors

This post will lay out some of the key differences between two motor types that exist on home sewing machines: brushed motors and brushless motors.

Brushed Motor

The vast majority of home sewing machines use a type of motor known as a brushed motor.

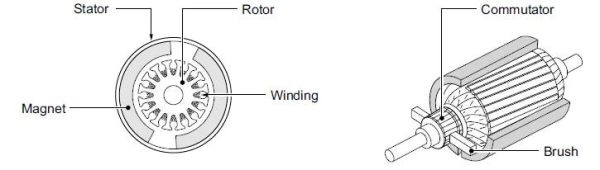

In a brushed motor, the rotor (the part that rotates) contains a commutator, which is a segmented metal ring that makes physical contact with the motor brushes.

The brushes are typically made of carbon or graphite and are spring-loaded to maintain contact with the commutator.

When an electric current is applied to the brushes, it flows through the commutator, creating a magnetic field that interacts with the stator (the stationary part of the motor), causing the rotor to rotate.

The brushes deliver power to the rotor through the commutator, but they also create friction and wear over time due to their physical contact. This friction can limit the motor's efficiency and lifespan.

Brushless Motor

Compared to brushed motors, brushless motors typically tend to be more energy-efficient and capable of higher speeds and power.

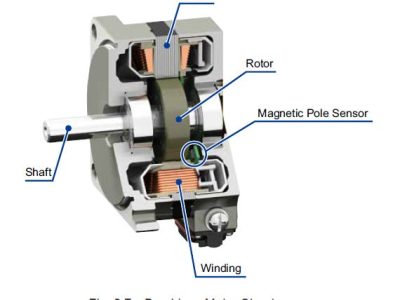

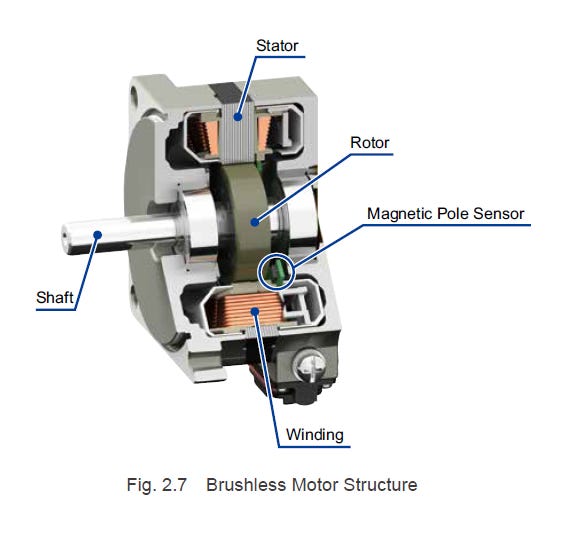

In a brushless motor, there is no physical contact between the rotor and the stator. Instead, the rotor contains permanent magnets, and the stator contains electromagnets.

The electromagnets in the stator are controlled electronically by an external circuit, typically using sensors or encoders to determine the rotor's position.

By precisely controlling the current to the stator electromagnets, the brushless motor can generate a rotating magnetic field that interacts with the permanent magnets on the rotor, causing it to rotate.

Since there are no brushes or commutators in a brushless motor, there is less friction and wear, resulting in higher efficiency, smoother operation, and longer lifespan compared to brushed motors.

It is rare for a home sewing machine to have a brushless motor, and much more common to see them paired with industrial machines. As far as I’m aware, the only home sewing machines equipped with brushless motors are the Janome Continental M-series machines: Continental M6, Continental M8, and Continental M17.

Example of a Worn Out Sewing Machine Motor

The photos below show the brushed motor of a Bernina 830 Record that was brought into our shop because the motor had stopped working.

- Worn out sewing machine motor

- Worn out sewing machine motor

Initially, we replaced the motor brushes because worn-out motor brushes won’t make adequate contact with the commuter, which results in the motor not running. But that didn’t fix the problem.

In the second photo, I zoomed in on the commuter, which is the gold-bronze surface within the motor casing. When the motor brushes wear out, a wire below the brush can become exposed. That is the case here: the exposed wire rubbed on the commuter so much that a groove has been worn into that surface. Due to this groove, even new replacement motor brushes fail to make adequate contact and generate power. Replacing the brushes (which isn’t a difficult fix) prior to the groove being worn into the commuter would have saved this motor. At this point, a new motor is needed

Brushless Motor on a Home Sewing Machine

Below are photos of the brushless servo motor used by the Janome Continental M6, Continental M8, and Continental M17.

- Janome Continental M8 Motor

- Janome Continental M8 Motor

- Janome Continental M8 Motor

For all you sewing enthusiasts out there, if you haven’t tried sewing on one of these Janome Continental machines before, I highly recommend you try it out. They aren’t the right machine for everybody, but they certainly have a special feel due to the special motor. Stop by our shop in Walnut Creek and spend a few minutes test-driving their floor model. I think you’ll see what I mean by “special feel.”

In Review

Brushed Motor:

- Simplicity: Brushed motors are simple in design compared to brushless motors, which makes them easier and cheaper to manufacture.

- Cost-effective: Due to their simpler design and construction, brushed motors are usually less expensive to purchase compared to brushless motors.

- Ease of maintenance: Maintenance of brushed motors is relatively easy. Replacing brushes is a straightforward process.

- Good for low-speed applications: Brushed motors are often preferred for low-speed applications where precise control is not critical.

Brushless Motor:

- High efficiency: Brushless motors are technically more efficient than brushed motors because they eliminate the friction and heat associated with brushes and commutators.

- Higher torque output: Brushless motors can produce higher torque compared to brushed motors of similar size.

Torque (M) x Speed (n) = Power (P) - Longer lifespan: Since brushless motors don't have brushes to wear out, they generally have a longer lifespan compared to brushed motors.

- Higher Cost: Brushless motors are typically more expensive to purchase compared to brushed motors due to their higher complexity and manufacturing costs.