Balancing Sewing Machine Tension

A Basic Guide to Balancing Sewing Machine Tension

When a sewing machine makes a stitch, it is essentially tying a knot between two sources of thread: the needle thread (upper thread), and bobbin thread (lower thread). When the sewing machine tension is balanced (good), the knot sits in-between the multiple layers of fabric we are sewing; it hides between the fabric, holding the fabric together.

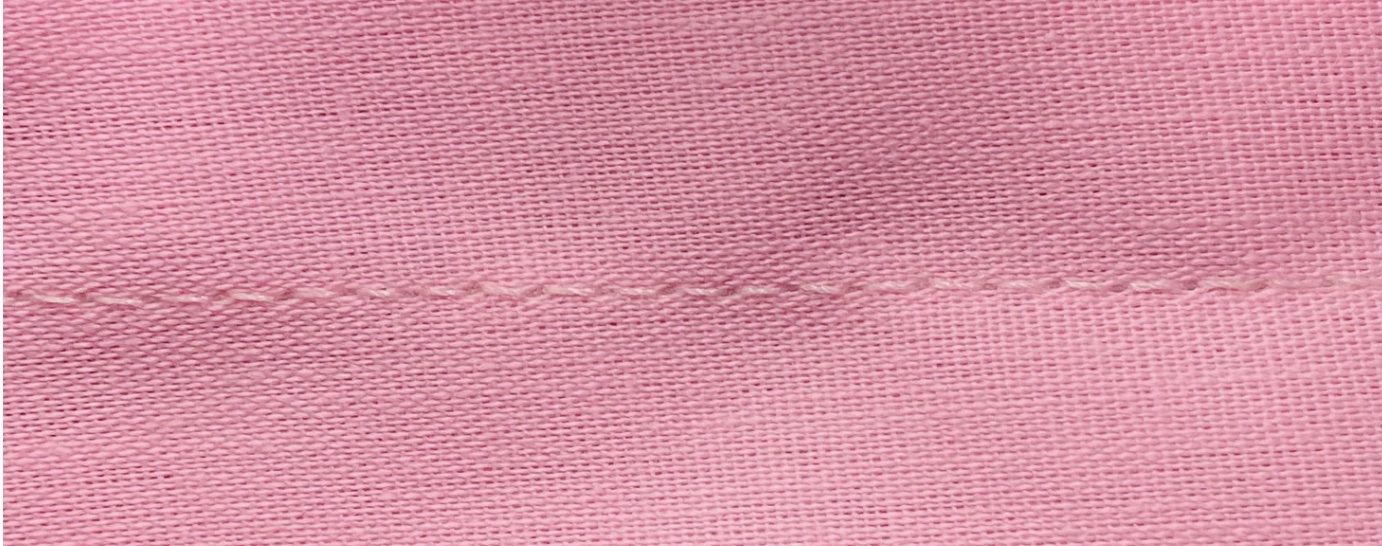

When the tension is unbalanced (bad), the knot will poke out one side of the fabric, either the top or bottom. In such cases, you might perceive the stitch as “loose” or “bumpy” or that the thread can easily be pulled out.

How to Balance (set) Tension on a Sewing Machine

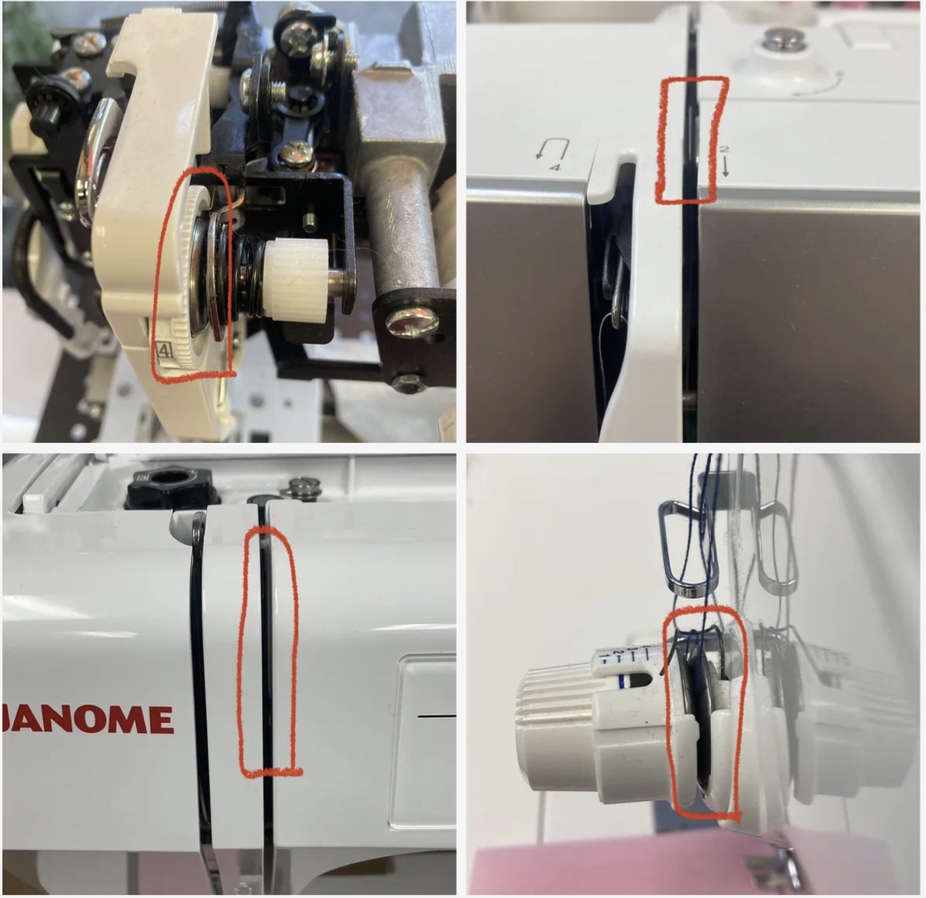

The thread that goes through the needle (upper thread source) begins at the spool and passes between the machine’s upper tension discs:

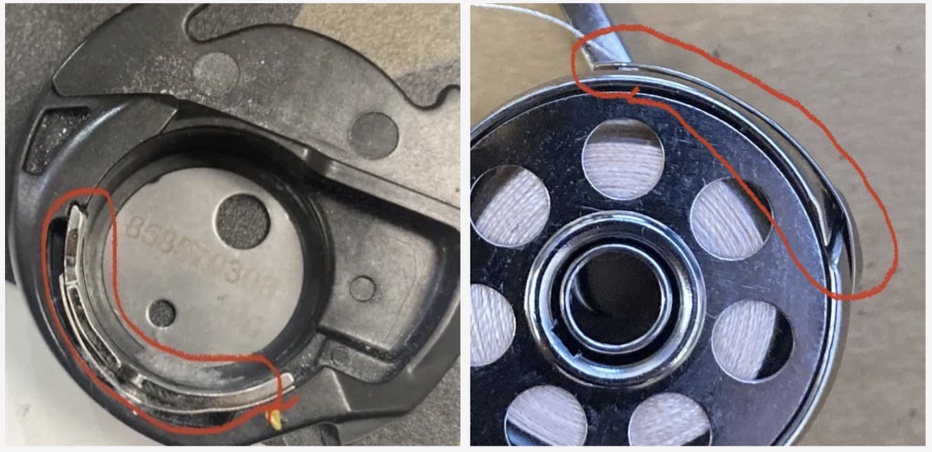

Meanwhile, your bobbin thread passes between the bobbin case tension discs:

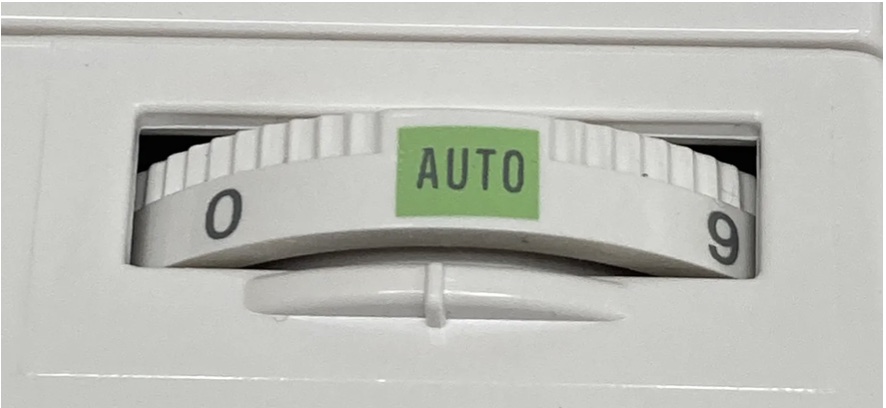

While we have the ability to adjust both the upper tension and bobbin case tension, I highly recommend you use the upper tension dial to balance tension. The bobbin case tension can only be adjusted by turning a very small screw that is sensitive and difficult to calibrate. Meanwhile, the upper thread tension dial is highly accessible to the user. It is most often numbered between 0 and 9, with 0 being the lightest tension and 9 being the tightest tension.

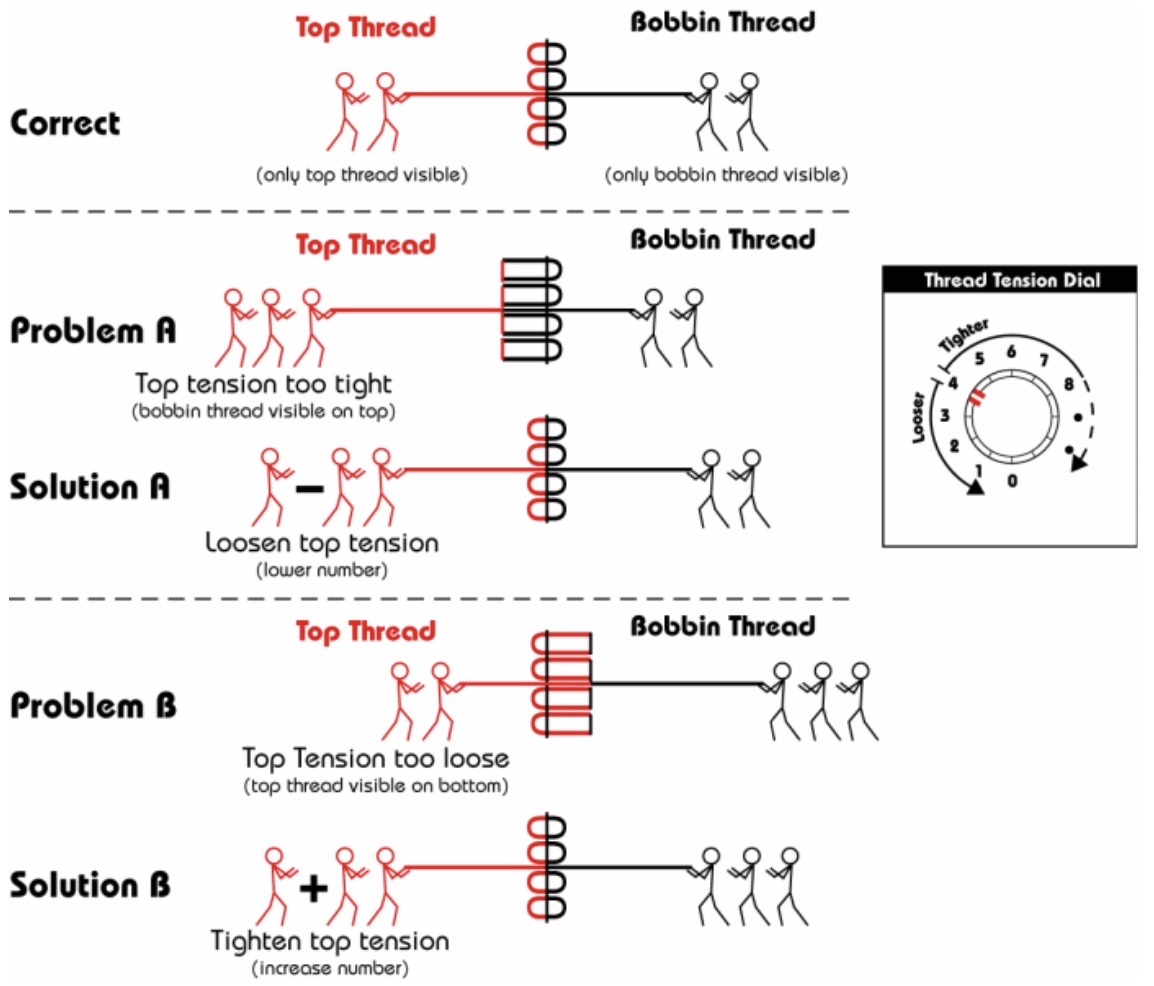

Think of tension as a tug-of-war between the upper thread and bobbin thread.

Remember, perfect tension means the knot sits in-between the layers of fabric we are sewing.

If the knot pokes out the topside of the fabric, that means the upper tension is overpowering the bobbin tension. In this instance, decrease the top tension (e.g. turn tension dial from 4 to 3) so that it’s easier for the bobbin case tension to pull the knot down into the fabric.

If the knot pokes out the underside of the fabric, that means the bobbin case tension is overpowering the top tension. In this instance, increase the upper tension (e.g. turn tension dial from 4 to 5) so that the upper thread can pull the knot back up into the fabric.

Typically, we should be able to achieve balanced tension with the dial set between 3 and 6, but there may be the rare occasion where I have to go all the way or all the way down in order to achieve a quality stitch. Don’t be afraid to use the full spectrum of the sewing machine’s upper tension dial. That 0 to 9 range exists for your benefit.

It’s okay to turn the dial to the extreme ends of the spectrum, but if you do need to go to 1 or 9 in order to get a good stitch, then there is something wrong with your machine and you should consider taking it to a trained sewing machine technician in the near future.

Notes on “Automatic Thread Tension”

Many modern sewing machines tout an “automatic thread tension” feature.

If a machine has “automatic tension”, it means the upper tension discs automatically adjust based on the stitch pattern that the user has selected. For example, your straight stitch tension will be set automatically at 4, but your zig-zag tension is automatically set 3.

In 2024, these “automatic” changes in tension are based on research from the manufacturers’ research and development teams. Essentially, they have made an educated guess as to what they judge to be the best tension setting on straight stitch, zig-zag, buttonhole, decorative, etc.

If you have a machine with “automatic tension”, but your tension is unbalanced, I recommend you set the upper tension to 4 and sew a straight stitch to see where the knot sits; then go through the tug-of-war tension re-calibration process described earlier.

Summary

- When the tension is balanced (good), the knot sits in-between the multiple layers of fabric we are sewing; it hides between the fabric, holding the fabric together.

- When the tension is unbalanced (bad), the knot will poke out one side of the fabric, either the top or bottom.

- While we have the ability to adjust both the upper tension and bobbin case tension, I highly recommend you use the upper tension dial to balance tension.

- If the knot pokes out the topside of the fabric, that means the upper tension is overpowering the bobbin tension, so the upper tension dial should be lowered.

- If the knot pokes out the underside of the fabric, that means the bobbin case tension is overpowering the top tension, so the upper tension dial should be increased.

Other Helpful Troubleshooting Articles

The Pull Test: the cure to thread loops on the underside of fabric

Puckered Fabric: why it happens and how to solve it