Sewing Machine Skipping Stitches?

Troubleshooting a sewing machine skipping stitches

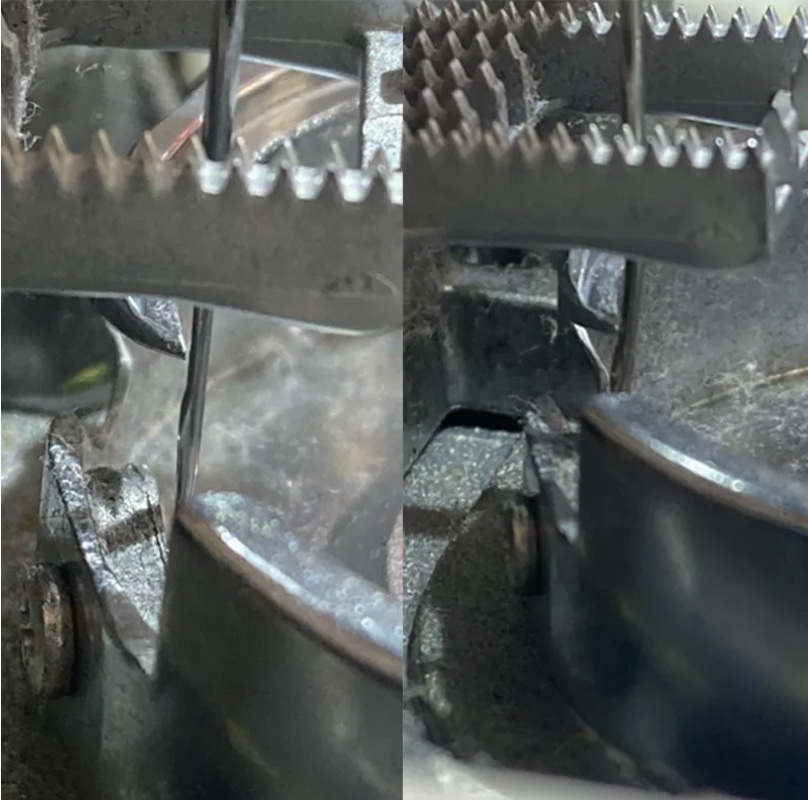

How a bent needle affect needle hook clearance & causes skipped stitches

Sewing machine skipping stitches? If you experience skipped stitches while sewing, the first step is to insert a new needle and rethread the machine.

Why?

A bent needle– even one bent ever so slightly– is among the leading causes of skipped stitches.

Skipped stitches occur below the needle plate when the hook point fails to pass through (or, catch) the thread loop that forms at the needle eye when the needle rises 2-2.5 millimeters above its bottom dead center position.

Assuming that the thread loop has formed properly, there are a handful of different ways that the hook could fail to pass through that thread loop:

- The hook could pass by the needle too far above the eye, before the thread loop is sufficiently formed (advanced needle-hook timing).

- The hook could pass by the needle underneath the eye, missing its chance to catch the thread loop that has already formed (retarded needle-hook timing).

- The hook could pass too far away from the needle, passing behind the loop (needle-hook clearance is excessive).

- The hook could pass too close to the needle, deflecting off the needle and affecting the hook's ability to pass through the loop (needle-hook clearance is too tight).

Theoretically, a needle bent severely to the left or right could simulate poor needle-hook timing; however, this is extremely rare. It is much more common that a bent needle would simulate poor needle-hook clearance and lead to skipped stitches.

What is needle-hook clearance?

As we established earlier, the hook is timed to pass behind the needle, just above the eye, as the needle rises 2-2.5 mm above its bottommost position. How far away is the hook from the needle as they pass? That distance is needle hook-clearance, and it must be precise.

Good needle-hook clearance:

- the needle and the hook are very close to each other, but not touching.

Poor needle-hook clearance:

- The needle and the hook can be too far away from each other, so that the hook passes behind the thread loop instead of passing through the thread loop.

- The needle and the hook can be too close together, so that the hook deflects off the needle, which also makes it difficult for the hook to pass through the thread loop.

Needle-hook clearance is a critical setting that can lead to skipped stitches if the needle and hook are too tight or too excessive in distance. The setting itself can get out of whack over time, which is something that will likely require a trained sewing machine technician to diagnose and fix.

However, a bent needle can often mimic needle-hook clearance being out of whack. Therefore, if you get skipped stitches and want to troubleshoot your machine without bringing it to a technician, I implore you to first insert a new needle and see if it fixes the problem. When I say new needle, I mean fresh out of the box. I don’t care if the needle currently in the machine has only been used for 1 hour, 1 minute, or 1 second— in order to confidently troubleshoot skipped stitches, we need a needle that I know has truly never been used before.

Chapter Summary

- If you experience skipped stitches while sewing, the first step is to insert a new needle and rethread the machine.

- It is common for a bent needle to simulate poor needle-hook clearance (and, theoretically, poor needle-hook timing), therefore causing skipped stitches.